24/7/365 Through long nights, weekends, holidays and almost all types of weather, drilling is taking place.

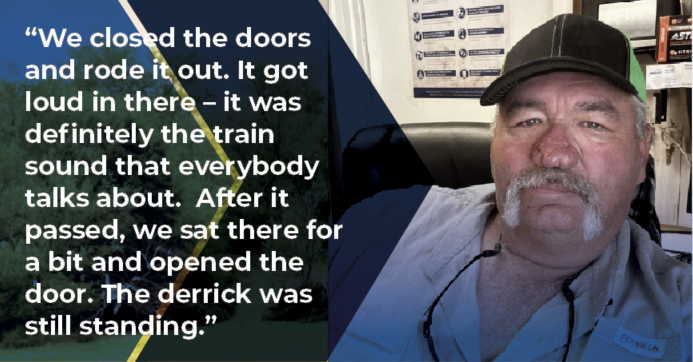

A mom and a rig manager – an unlikely pair, but as I sat down to interview Tony Maynard, H&P employee of 17 years and Rig Manager of over a decade, I learned that we had much more in common than you’d think, as he gave his firsthand account of a tornado hitting his drilling rig.

While my children can sometimes be compared to small tornados, that’s not what I mean. Tony’s account of his experience demonstrates the importance of staying aware and alert at all times, with the safety of those you’re responsible for as your highest calling. The demands of the job are high – around the clock, for the both of us, there’s a job to do.

Drilling rigs are inherently exposed to the elements. Equipment must be designed to withstand some of the most severe environmental conditions, with drilling taking place in nearly all climates around the globe. Desert sands in the Middle East provide constant sandblasting effect and rigs must be outfitted with larger tires to move efficiently from one location to the next. Feet of snow can accumulate in the northernmost rig sites. Maybe you’ve seen North Sea TikTok?

As the Shale Boom has progressed in the United States, unconventional long lateral wells are drilled in areas that encounter severe thunderstorms and tornadoes on a regular basis. As a native Oklahoman, I’ve grown up knowing how to “take cover” during a tornado warning, but most Oklahomans have never actually experienced being in the path of a tornado.

Crews on drilling rigs must expect tornadoes as a very real possibility, and Tony Maynard, H&P employee of 17 years and Rig Manager of over a decade, can give a firsthand account of a tornado hitting his drilling rig.

“I definitely won’t forget April 19, 2023. We had just started running our production string casing, there was roughly 21,000 feet of pipe in there. We had 2,500 feet of casing in the hole. Between my superintendent calling in to just tell me to watch over the weather, and my safety people were doing it as well. We knew something bad was coming our way. I was watching it too when I realized it was coming in our direction.”

Drilling sites are host to a high activity operation. Depending on the stage of the well, the operator and drilling contractor, there are a number of various third-party service companies coming and going on location in order to complete their task. The rig manager must always monitor these teams to ensure all are prepared at a moment’s notice for a potential safety incident, crew evacuation, or in Tony’s case, taking cover in an underground storm shelter installed on location.

“We closed the doors and rode it out. It got loud in there – it was definitely the train sound that everybody talks about. We waited things out, steadily getting texts from everyone telling us to watch out. I lost service down in there and couldn’t reply to the superintendent and HSE staff, but we sat there and waited. We were down there probably 15 or 20 minutes. After it passed, we sat there for a bit and opened the door. The derrick was still standing.”

After investigating the scene on the two-well pad, it was obvious that the rig was on the path of the tornado with equipment scattered around the pad. Ropes were ripped off drill pipe, increasing the likelihood of dropped tubulars. Untethered 90-foot sections of steel drill pipe are not to be taken lightly.

“The superintendent was trying to get to us, but it was pretty bad all around there – roadblocks everywhere. If we resumed operations and something were to happen to somebody out there, we wouldn’t be able to get any help to them. We shut down operations that night and waited until the next morning to assess the situation.”

The next day, Engineering arrived, drones in tow.

“We had damage to the derrick board. We ended up laying down casing after the engineers came out with drones. It all had to be inspected before we could even move the blocks. And before the crew could even go up, we had a drone inspect pens and make sure nothing was torn loose.”

After a thorough inspection, it was determined that the damage incurred to the derrick board was severe enough to warrant a change out. Once the tasks of laying down casing and drill pipe were completed, the derrick was then lowered and replaced. The crew was cleared to resume drilling ahead.

“Yeah, that was April 19. Then on May 11, we had another one, right across the highway from us. You could chunk a rock at it.”

Drilling in remote locations – whether in the middle of the ocean, the middle of a rainforest, or the middle of rural Oklahoma – brings its own set of issues when inclement weather takes place. Multiple methods of monitoring exist in the event that systems are unavailable. The Starlink satellite system on all H&P rigs, storm radios, high tech rig phones, and even a basic antenna for local channels all ensure accurate and up to date weather information is available.

“This is Oklahoma, so you’re going to get tornadoes. There wasn’t anything we could have done differently. You always have to communicate, and make sure everyone is aware of the situation and get them all to safety.”

Two tornadoes in one month is a rarity, but it’s an occurrence that rig leadership anticipates each year, in the spring and summer, in Tornado Alley.

“We really emphasize it in the spring. We remind our crews that it’s getting to be storm season, and it’s time to make sure we know where we’re supposed to go, and we understand the processes during severe weather. We review the procedures for shutting in a well if we have to suspend operations temporarily.”

Oklahomans can be quick to assume that everyone is familiar with these procedures, but it must be reviewed frequently as the workforce churns in a volatile market. Rig crews move from place to place just as rigs are relocated over time

Tony’s time with H&P has been spent across the United States – Central Texas, South Texas, Colorado, and Ohio. But Oklahoma, he says, seems to feel the most like home.

“You get those like me, from East Texas – we get tornadoes there but it’s not Tornado Alley like Oklahoman seems to be through here. I had already been dealing with situations like this – close encounters before, but nothing like what occurred last year. That’s the closest an H&P rig has ever been to a tornado, according to our records . You’ve got to always expect bad weather. Even if it’s even if it’s not a tornado, just the lightning strikes and having somebody on the derrick while you’re tripping pipe, getting them back down to safety.”

“It’s not like you train for a ‘just-in-case’ situation. We’re expecting it to happen here. If it doesn’t happen, then you got lucky. That’s what I try to teach my crew.”

The night a tornado hit an H&P rig, another woman was up, making sure Tony Maynard was safe and cared for from afar.

“My phone was blowing up all night long, and on top of that, I had my wife doing it as well.”