FAIL SAFELY!

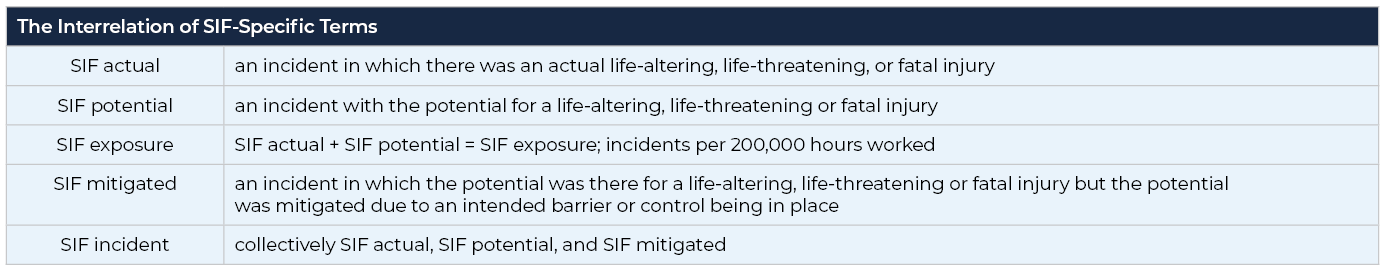

We hear the term quite often within the drilling industry. But what does it really mean? Is it even possible to achieve in an industry that operates daily with elevated risk factors? We know it to be true: equipment will fail, and as long as people are involved in the work, failure from human factors is inevitable at some point. However, it is possible for failures to occur in the workplace while maintaining worker safety. In fact, this is what we all should be striving to achieve. That’s why the concept of a “SIF-mitigated” category was introduced – framing these mitigated incidents in a positive light, representing the ability to fail safely.

Consider two hypothetical scenarios involving falls from heights. In the first scenario, an employee was working on top of a mud tank approximately 10ft above the ground after setting the equipment. The handrails had not yet been set in place, and the edge was unprotected. Although readily available, the individual did not wear any fall protection. While conducting their work near the unprotected edge, they fell from the tank and sustained life-ending injuries. Now, consider a second scenario involving a fall from the same tank with remarkably similar details as the first. However, this time, the employee was wearing proper fall protection. Instead of hitting the ground, their harness and lanyard operated as designed and stopped the fall. The employee comes out of the incident virtually unscathed. In the second scenario, what happened? The employee failed to maintain secure footing and fell from the tank just as in the first scenario, however, due to the proper controls (fall protection) being in place, the employee was able to fail safely. The message is clear: effective controls can help mitigate exposure to SIFs.

Years ago, the automotive industry recognized that it was impossible to prevent all automobile accidents. Instead, they shifted their focus to protecting passengers during accidents. Similarly, our own shift to the Actively C.A.R.E.® philosophy empowered our workforce to Control And Remove Exposures if failures occur. However, helping to ensure worker safety when failures occur requires more than just this philosophy – it demands operational discipline, adequate training, thorough pre-job planning, psychological safety (1) and continuous learning from failures to implement effective controls.

Failure is inevitable – it’s a reality we must accept. What truly matters is how we prepare for it. Reflecting on the scenarios discussed earlier, we must be confident that we are all doing our part to implement effective controls that will mitigate the exposures to our workforce. By taking these steps, we can face failures with confidence and ultimately… fail safely.

Remember: Any work performed at a height over 4’ should be considered “working at heights” and requires 100% tie-off

Citations (Link to psychological safety):

What is psychological safety at work? Here’s how to start creating it. (2023, December 4). American Psychological Association. https://www.apa.org/topics/healthy-workplaces/psychological-safety