True Single-Button Execution

Challenge

In a volatile and unpredictable industry, immediate cost savings can be of incredible value. One way to achieve this is by reducing the number of on-site field employees through automation:

In addition to the direct benefits of automating the directional drilling process, the H&P Bit Guidance System, partnered with AutoSlide® technology, decreases the number of personnel needed to drill the well.

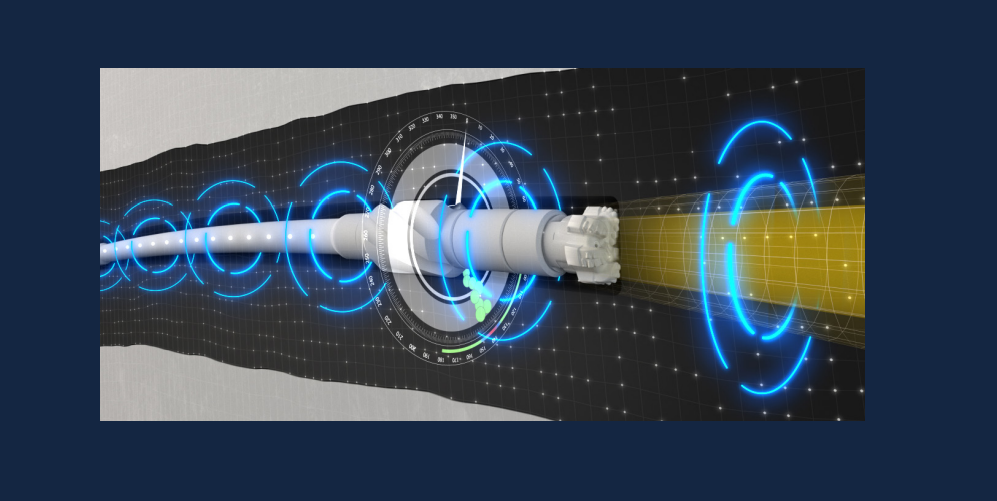

The Bit Guidance System uses task automation, forward modeling and automated decision making to guide the driller for more accurate positioning of the bit while drilling horizontal wells. AutoSlide technology receives the sliding instructions from the Bit Guidance System and automatically orients and holds toolface by controlling the rig equipment. The technology performs the slide in a true single-button execution.

Examples of current demanning efforts using the Bit Guidance System and AutoSlide technology include:

OPErator 1 - Eagle Ford

All rigs are 50% demanned with plans to reduce headcount to 100% in the future.

OPErator 2 - permian basin

Two rigs are 100% demanned with plans to extend demanning on an additional rig.

OPErator 3 - permian basin

One on-site H&P directional driller on each rig.

Outcome

Near-immediate cost savings

Present-focused reduction of labor costs.

Increased safety and reduced health risk

A lower number of on-site personnel through automation reduces exposure to the rig floor environment, decreasing the risk of a significant injury or fatality potential and reducing operator liability.

Better quality of life and higher quality support

Redefining the roles in historical workforce to leverage top talent through the experience multiplier of digitization instead of spreading human experience thinly across many drilling rigs.

Efficiency and predictability

Removing the human factor and automating the decision-making process creates a more predictable wellbore. The transition from art to science creates repeatability across all rigs leading to more accurate financial projections.

Consistency is the basis for optimization

Demanning through automation allows the operator to identify and implement additional areas for improvement. Drilling program consistency, through reduced variables, enables a performance improvement environment.

Past performance is not a guarantee of future results. Any statements regarding past performance are not guarantees of future performance and actual results may differ materially. © 07/2020 HPCS010