Bit Guidance System Helps Operator Avoid Sidetrack and Hefty Costs

Challenge

An operator in South Texas was aiming to land their curve with pinpoint accuracy in order to accomplish their desired outcome of maximizing well production. The directional driller, geologists, and reservoir engineers were all working together in order to try and avoid “landing long” or “soft”, which can both have adverse effects such as requiring a large dogleg, reducing production, or potentially requiring a plug-back and sidetrack.

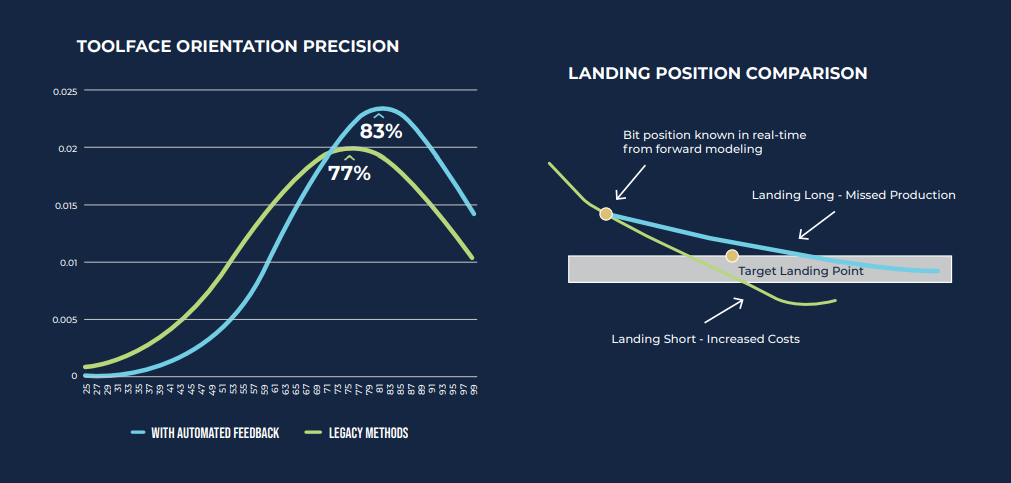

Traditionally, directional drillers have used surveys and estimates in order to perform these calculations, however projections and assumptions are and will continue to be inconsistent by nature. Additionally, maintaining a high toolface precision while drilling through varied geological formations require a directional driller to have specific local knowledge and experience. The lack of this can result in sections of both good and poor toolface control while sliding.

Solution

H&P discussed these challenges with the operator and encouraged them to embrace automated technology to reduce uncertainty and maintain consistent, reliable results. H&P’s automated Bit Guidance System makes intelligent decisions based on economics and delivers real-time information, like slide reports, survey reports, drilling parameters and well plan information.

Outcome

By utilizing automated rig state detection, toolface orientation, recent dynamic motor yield and motor potential while sliding, and recent BHA tendencies while rotating, the H&P Bit Guidance System determined that the 29 degrees inclination projection that was calculated via legacy methods by the human directional driller was incorrect, and its actual value was a 25 degree inclination.

The reason that the traditional calculations were incorrect in this case were because the assumption of consistent performance was violated; and the motor yield ahead of the last survey was actually much lower. The Bit Guidance System however, analyzed the data in real-time and indicated that the driller had relatively accurate toolface control while drilling prior the last survey (72%) and poor toolface control while sliding after the last survey (54%). Toolface precision often varies because of numerous variables, but it is known that a toolface precision greater than 90% delivers motor yields close to the full motor potential, while toolface control at less than 50% are doing more harm than good.

Additionally, the higher accuracy of the bit position and trajectory by the Bit Guidance System determined a longer slide interval to precisely land the curve (the automated Bit Guidance System determined a 67 ft slide would be required, which is 25 ft longer than determined using a non-automated process).

Because this automated technology had only been newly introduced to this operator, there were naturally reservations on trusting machine over man. As a compromise, the driller decided to split the difference between the two methods (manual and automated) and slide 57 feet. After drilling the next stand, a survey was acquired showing an inclination of 32.6 at the sensor and a “build rate to land” was calculated as 7.8 degrees per hundred feet. This required nearly 100% sliding to land the curve. If the driller had performed the shorter slide as determined using legacy projection methods, he would have landed short, which would have led to a sidetrack and additional costs.

The automated system estimated the position of the bit with more accuracy because it used more of the available data along with automated forward modeling algorithms to utilize this data in real-time. In the case study, the directional driller did not fully follow the algorithm, however they did increase the footage slid. In this instance, the algorithm actually saved a bit trip.

The H&P Bit Guidance System automates across the four cognitive functions: acquiring data, analyzing data, deciding actions and implementing actions; and can provide additional previously untapped value by reconfiguring roles, responsibilities and workflows.

With most of the heavy cognitive lifting performed by a machine, a single directional driller can now work remotely and manage the directional control of multiple wells simultaneously. Automation also provides the directional driller time for further analysis of data in a structured scientific manner.

The proficiency accrued via in-field experience can automatically inform decisions made by the system such that there is limited loss in competence due to shift or personnel changes. Thus, the knowledge and data gained by drilling previous wells, or with a specific tool configuration or a specific basin can be used to automatically improve future wells. Mistakes can be reduced by near instant transference of experience.

Past performance is not a guarantee of future results. Any statements regarding past performance are not guarantees of future performance and actual results may differ materially. © 10/2021 HPCS016