Proven Reliability Gives Major Operator Confidence to Increase Build Rate

Challenge

A major oil and gas operator was interested in implementing technology and automation solutions for their Eagle Ford operations. Specifically, the customer was looking to land more curves in the zone, increase the rate of penetration (ROP) during the curve phase of drilling the wellbore and maximize hydrocarbon extraction per well.

Solution

The operator utilized a combination of H&P’s super spec rig fleet, technology and automation to add increased value to their operations. In addition to the rigs, they also added a custom package of technologies to add increased value to their operations.

Helmerich and Payne offers software applications that layer on top of the FlexRig® fleet drilling control system and provide machine/human collaboration during the drilling process to improve efficiency. In this case, the operator used one such technology called FlexOscillator®. This rig control software automates drillstring rotation, reduces drag, and decreases costly incidents of stuck pipe.

In addition to FlexOscillator technology, the customer also used H&P’s Bit Guidance System to steer the bit in real time. The Bit Guidance System uses task automation, forward modeling and automated decision-making to guide the driller for more accurate positioning of the bit while drilling horizontal wells. The technology helps improve overall operating economics by lowering well construction costs, reducing future lifting costs, and increasing hydrocarbon production potential.

AutoSlide® technology works together with the Bit Guidance System, receiving the sliding instructions and automatically optimizing parameters and orienting and holding toolface.

Outcome

The combination of rigs and technologies allowed the customer to achieve remarkable results in their Eagle Ford operations.

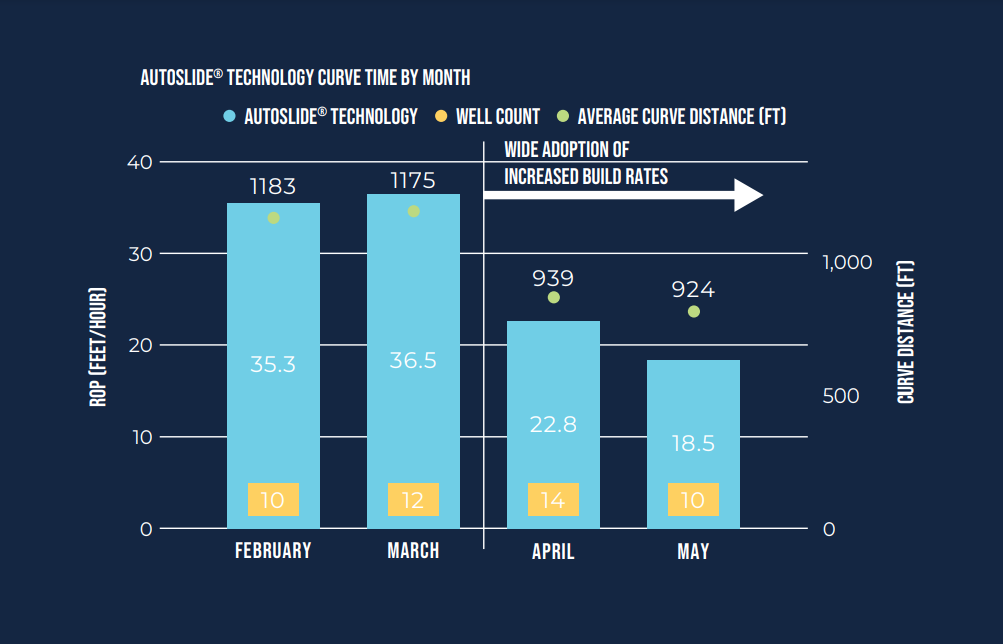

The reliability of AutoSlide technology to deliver curves drove the operator to change their plan build rates from 8 degrees to 10 degrees, which allowed for a faster curve time (ROP).

The outcome was an increased vertical section, or additional lateral footage, which could result in increased hydrocarbons while reducing overall drilling time.

The operator was so impressed by the results that they are trialing 11 degree build rates, and are ultimately aiming for 12 degree build rates, potentially increasing those benefits.

Because this comprehensive solution allows for the de-manning of directional drillers from location, the operator also saw cost and HSE benefits by reducing personnel onsite.

Past performance is not a guarantee of future results. Any statements regarding past performance are not guarantees of future performance and actual results may differ materially. © 06/2022 HPCS006