Challenge

An operator drilling out of the Meramec formation in Oklahoma historically struggled with suboptimal rates of penetration (ROP) due to stick slip and whirl. It caused premature tool failures and bit damage and increased the nonproductive time and costs.

They turned to H&P for a solution to enhance drilling efficiency and preserve bit life.

Solution

Based on the desired outcome th

e operator was looking to achieve, H&P recommended the Autodriller control system in conjunction with FlexDrill® technology. The continuous, automatic optimization of these solutions helped increase ROP and lower mechanical specific energy (MSE), leading to a more efficient drilling process for the operator.

Outcome

The proprietary FlexDrill technology perf

ormed continuous drill off tests to find the optimal drilling parameters through each formation. This process mitigated stick slip and whirl dysfunction, reducing the downhole vibrations responsible for bit and bottom hole assembly (BHA) damage. Additionally, H&P’s solution automatically staged the drilling set points after tagging bottom to further reduce risk and accelerate the well program.

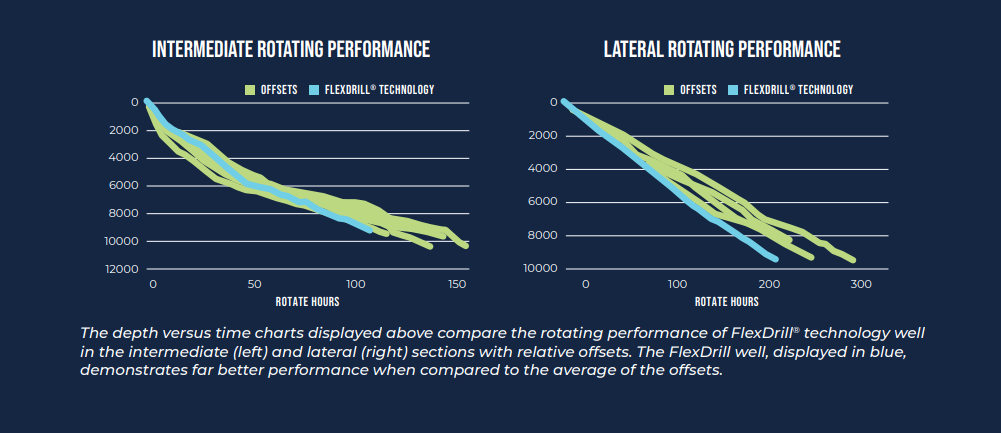

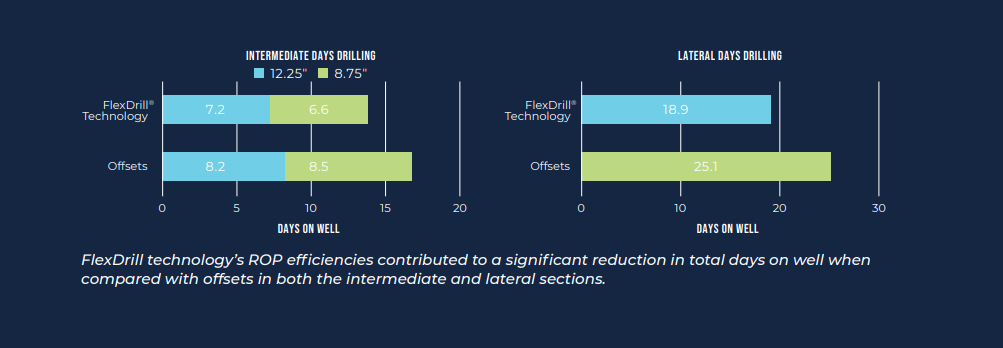

Overall, H&P helped the operator outperform all offsets in both the intermediate and lateral portions of the well.

Increased ROP

The rig improved their spud to total depth

time by five days, resulting in a 12% overall savings.

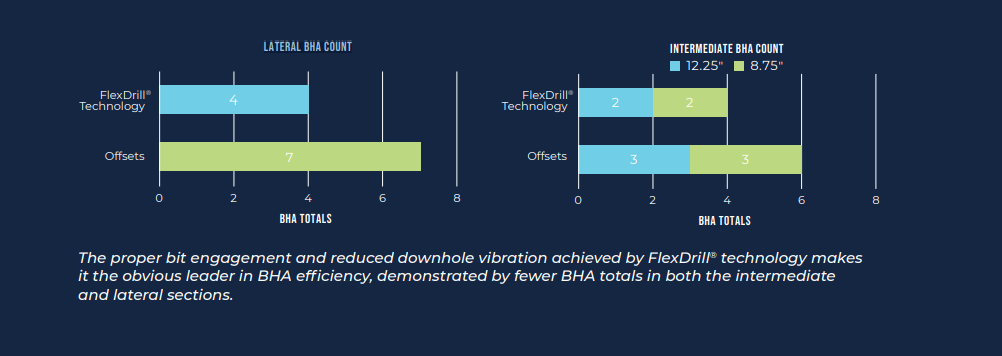

Reduced BHA Count

There were four less BHAs used throughout the well, translating to a 30% reduction.

Record Breaking Performance

The Tonkawa formation interval was drilled to casing point in a single run.

Past performance is not a guarantee of future results. Any statements regarding past performance are not guarantees of future performance and actual results may differ materially. © 06/2022 HPCS019