Improve Your Data-Driven Decisions and Increase Asset Value

Wellbore positioning comes with high levels of uncertainty due to error sources inherent in the surveying process. If not accounted for, these errors can result in loss of production, equipment failure, and non-productive time, leading to potential exposures and/or costly situations. By reducing uncertainty with better data, decision makers can have more confidence in the decisions they make - impacting overall performance for optimal outcomes.

Below are three ways to use better data and to use that data better so you can improve your data-driven decisions and increase asset value.

1. Well Trajectory: Improve Execution by Reducing Uncertainty

Engineers do their best with the data they are given - so give them better data.

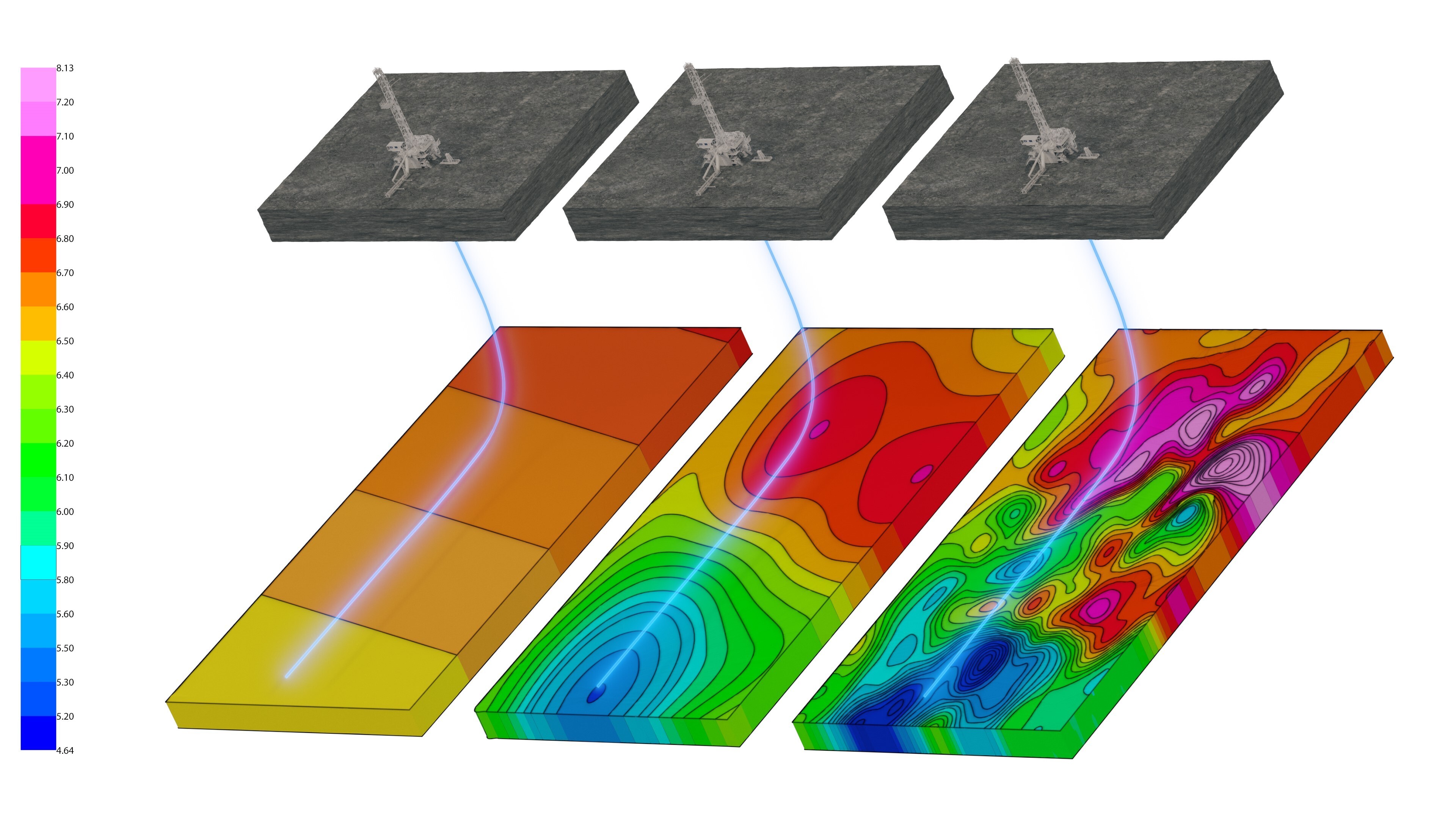

Without an actual GPS downhole, engineers rely on combining directional measurements that come with inherent errors. Magnetic MWD surveys measure wellbore orientations throughout the well which are combined to give a wellbore position using minimum curvature. These orientation measurements are impacted by errors such as uncertainty in North reference, magnetic interference, misalignments, calibration errors and data frequency.

Think about the disconnect between the size of a driller’s target window (~30 ft) and the amount of uncertainty that may exist in the wellbore position at the end of a long lateral (~300 ft). With well objectives such as well spacing, collision avoidance concerns and lease lines relying on such narrow windows, oftentimes a traditional 300 ft uncertainty is insufficient to confidently place a well, even if all drilling practices are perfectly executed.

While decisions on how to survey are assigned to the Drilling group, these decisions impact nearly everyone who will work with the well, from running casing and installing pumps, to production analysis and future campaigns.

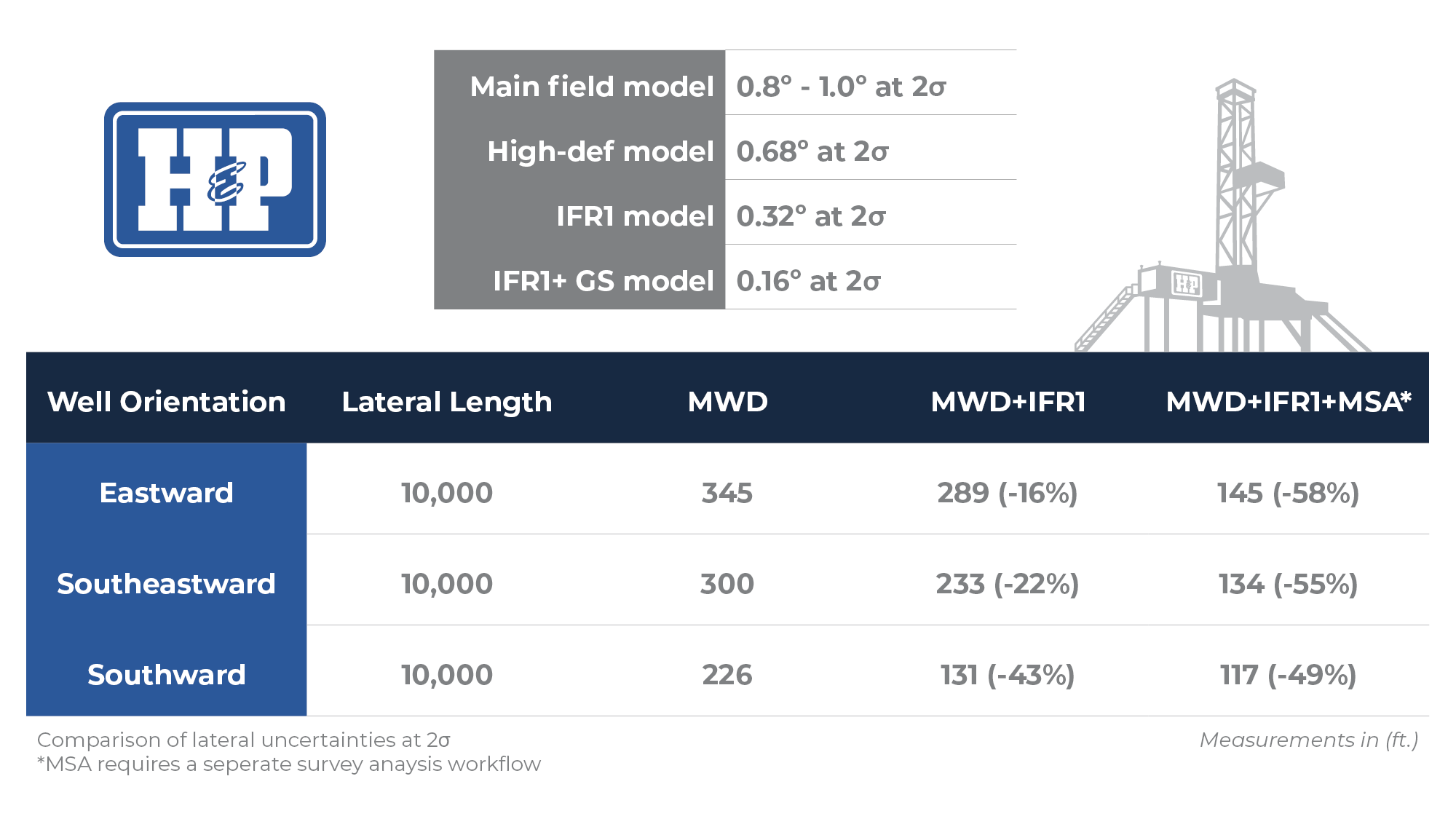

That is what makes accurate wellbore positioning an important piece to the overall health of a drilling operation. Accurate data empowers confidence because of the elimination of unknown variables. With H&P Survey Management, we are able to reduce uncertainty by nearly 60% in some scenarios. Decision makers make better decisions when they have better data at their disposal. Improving the data you leverage to make decisions helps improve performance execution by significantly reducing positional uncertainty.

2. In-Field Referencing (IFR): Accurate Data is the Catalyst for Better Decisions

“A lack of precision is dangerous when the margin of error is small,” Donald Rumsfeld.

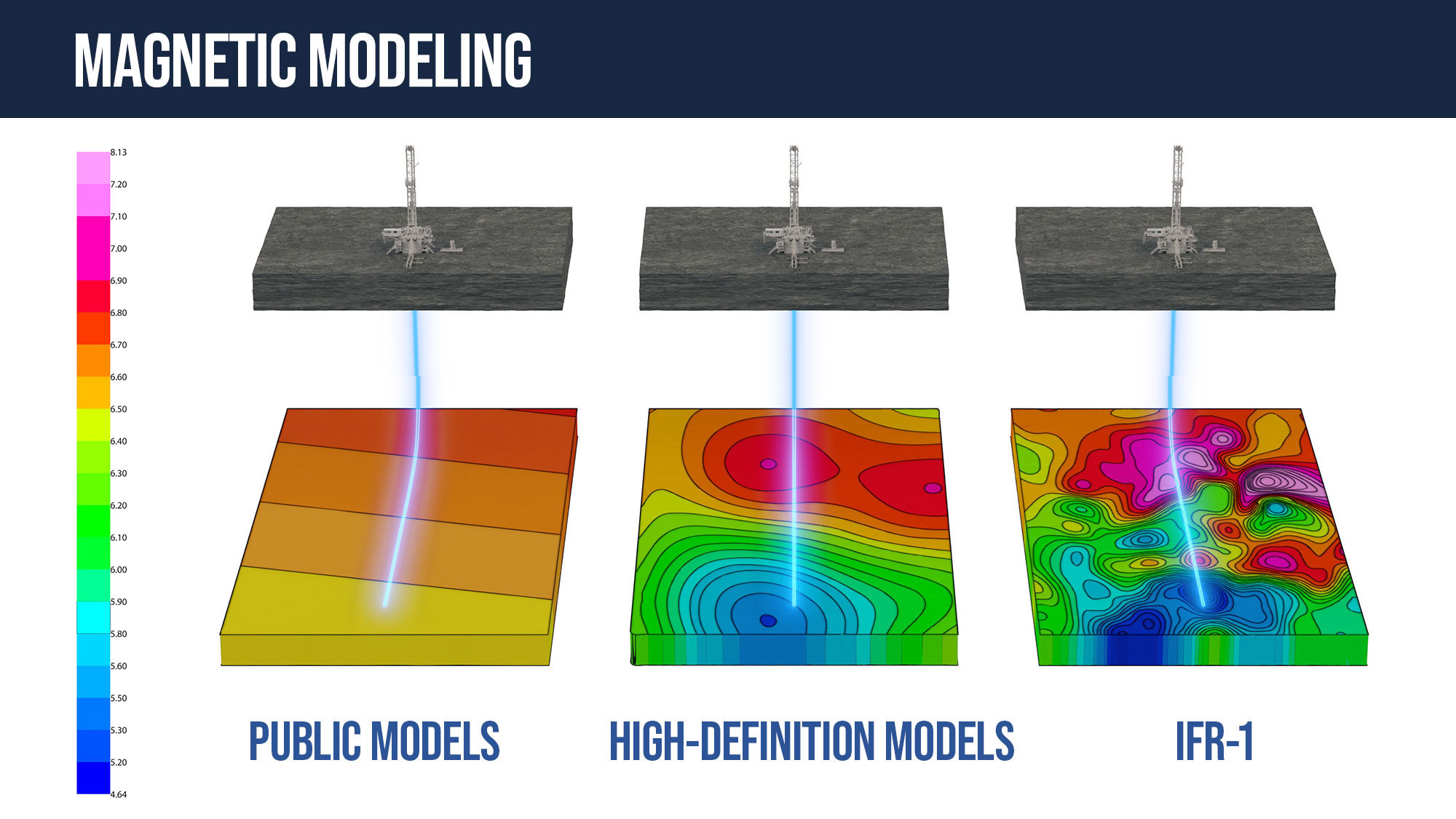

Magnetic models are a critical piece of the magnetic surveying process. Increasing the resolution of a magnetic model can lead to substantial reductions in positional uncertainty. Leveraging satellite data, local observations, and direct measurements can reduce declination uncertainty from 1° to 0.16° at 2-Sigma. This error has a direct impact on azimuth measurements and could result in a horizontal difference of over 140 ft over a 10,000 ft lateral.

Empirical measurements of the geomagnetic field also help ensure confidence in the data and allow for the observance of other errors early in the drilling process.

3. MWD Analytics: Optimizing Better Data

MWD analytics leverage powerful algorithms to help eliminate systematic errors in the surveys collected by a MWD tool. This ranges from common error sources such as drillstring interference and calibration errors to less obvious issues such as misalignments and magnetic mud.

Highly trained engineers analyzing each individual survey in conjunction with automated solutions offers consistently reliable and timely corrections to directional data.

An additional note from the authors: A culture focused on education and transparency also helps ensure that communication is always available when it is needed, while a focus on “management by exception” focuses on escalating issues when needed and operating smoothly in the background when it is not. This approach allows operators to focus on their many other important tasks while survey data can be left to Survey Management experts. Think - always available, never overwhelming.

Want to improve wellbore placement?

To learn more about how H&P leverages Survey Management to deliver better drilling outcomes to operators, connect with our sales team. Click the link to open a chat.