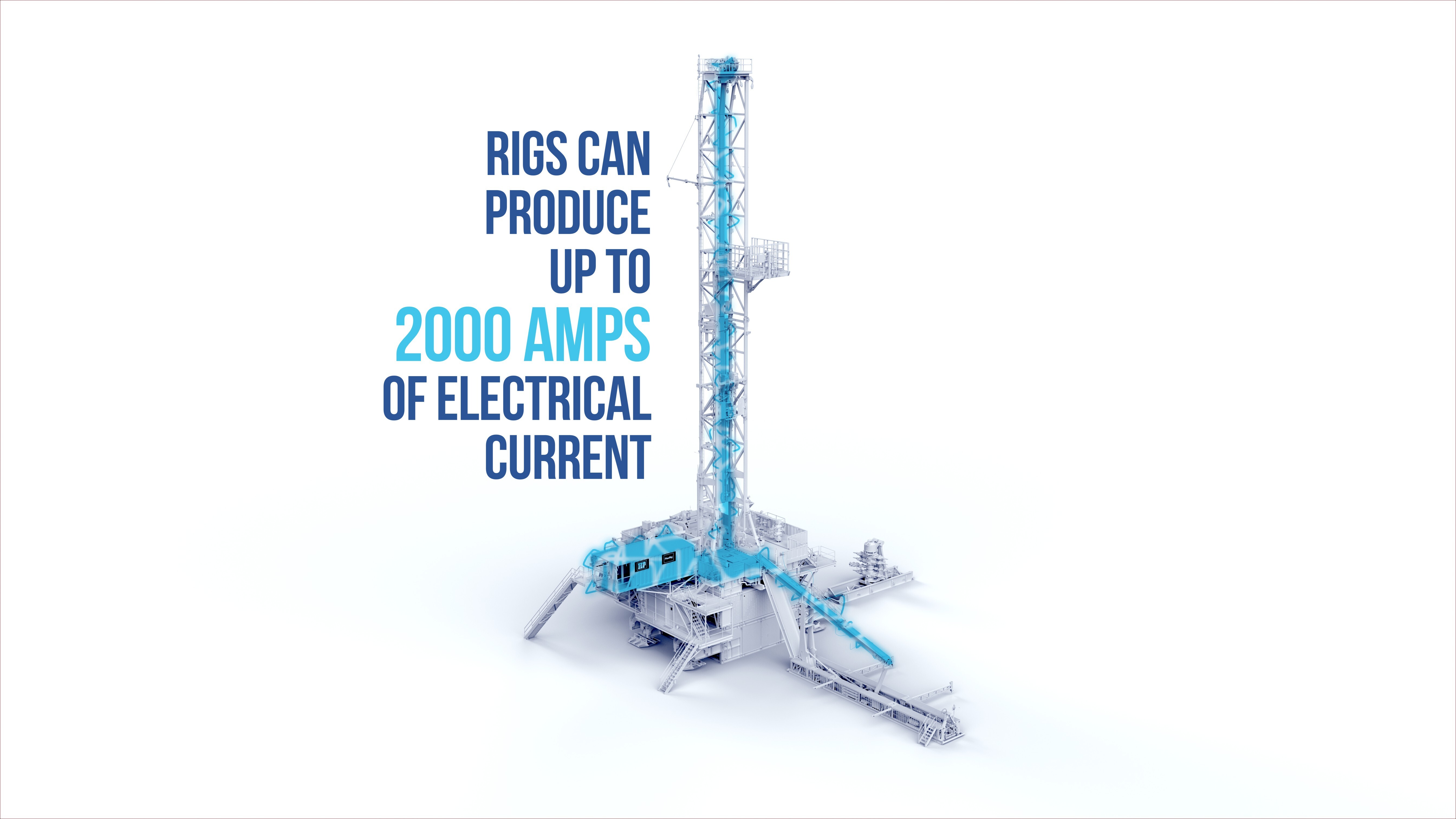

Energy exposure in the workplace poses a significant threat to workers’ safety. Based on data reported to OSHA from the Electrical Safety Foundation, in 2020 alone, electrical shock incidents claimed the lives of 126 workers, emphasizing the critical need for proactive measures to safeguard our workforce. The energy exposure risk does not just apply to field electricians: 70% of workplace electrical related incidents involved nonelectrical workers. While working on a drilling rig, all workers are faced with many forms of energy that could lead to a serious injury or even a fatality.

Powerful mechanical equipment on drilling rigs generates high levels of energy, posing a serious risk without proper controls in place. If that power is not controlled properly, it could lead to a serious incident.

Rig-based employees work around mechanical and electrical energy every day. However, there are situations where exposure to these forms of energy is increased.

Let’s examine common energy exposure situations on a drilling rig and strategies for effective risk mitigation.

INCREASED EXPOSURE DURING RIG MOVE OPERATIONS

Rig move operations stand out as periods of heightened exposure to mechanical and electrical energy. Tasks performed during rig down/power down, such as handling cables and disconnecting plugs, carry significant risks. Especially when conducted while portions of the rig are still operational, chances are greatly increased that an employee will contact energized cables, components, or equipment.

EQUIPMENT DAMAGE AND ELECTRICAL EXPOSURE

Moving equipment from one location to the next can result in equipment and component damage, particularly to cabling. Unaddressed damage can lead to substantial electrical exposure for employees. Similar risks apply to high-pressure hoses related to hydraulic systems and mud lines.

RIG UP PROCESS CHALLENGES

Rigging up after a move commonly requires interaction with cabling, plugs and receptacles, and high-pressure lines amid powered-up rig sections, increasing the chances of unintended equipment operation. Inadequate LO/TO/TO procedures during power down amplify the risk of unplanned equipment operation or accidental contact with energized receptacles.

LABELING CHALLENGES AND OPERATIONAL EXPOSURES

Labeling issues, often exacerbated by the harsh rig environment, can lead to incorrect equipment connections, and expose workers to mechanical and electrical energy.

Rig moves are not the sole source of energy exposures; exposures exist during normal drilling operations as well. For non-electrical workers, a general lack of understanding around the power distribution system can lead to incidents or events during routine drilling operations. Changing weather conditions also contribute to increased exposure.

HOW DO WE CONTROL AND REMOVE THESE ENERGY EXPOSURES?

As an industry we must commit to the following:

We know that electrical exposures can create the potential for a safety exposure to personnel on a drilling rig site. We also know it is important to have strong processes in place to help mitigate our exposure to energy as we Actively C.A.R.E. for ourselves and others. Mitigating these risks requires the development and refinement of robust processes and procedures, with worker input being key to ensure effectiveness and adherence. As the industry continues to evolve, so too must our commitment to safety, reflected in evolving processes, policies, and training practices. By prioritizing worker safety and fostering a culture of continuous improvement, we can effectively combat energy exposures and create a safer working environment for all.