REDUCE WELLBORE PLACEMENT UNCERTAINTY BY UP TO 60%

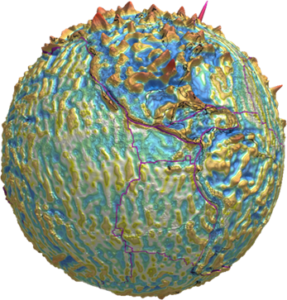

Drilling practices alone are not enough to accurately deliver a high quality wellbore, as success is equally dependent on the accuracy of the wellbore survey. H&P Survey Management delivers advanced, real-time MWD survey corrections to enable precise well spacing, enhanced placement within formations, and better knowledge of offset wellbore locations.

Start Making Data Driven Decisions. Your Wellbore is Only as Good as Your Survey.

SMOOTH OPERATIONAL PROCESS ENABLES PAINLESS IMPLEMENTATION

- Automated quality control and data processing

- API connections to third party software

- Trusted, technical experts provide procedures and best practices to help ensure survey success

- Operations to scale without compromising service quality

Achieve A Better Outcome with Advanced Wellbore Placement

- Survey Management helps ensure that the position used for both the Bit Guidance System projections and Collision Avoidance calculations are accurate and confirm it passes quality requirements. Learn More

- Bit Guidance System estimates the bit location using the actions already performed (sliding and rotating), then it further defines the actions that will be performed for the next 300-1,000 ft. (called the convergence plan). Learn More

- Collision Avoidance technology automatically takes the Bit Guidance System convergence plan and confirms if it passes the risk management anti-collision policy. If there is any need for escalation, the convergence plan is immediately flagged so special action can be taken and issues can be resolved. Learn More